Element Trees: Roughing Step

This section describes how to construct and access the element tree for a milling roughing feature. It also describes how

to create, redefine, and access the properties of these features.

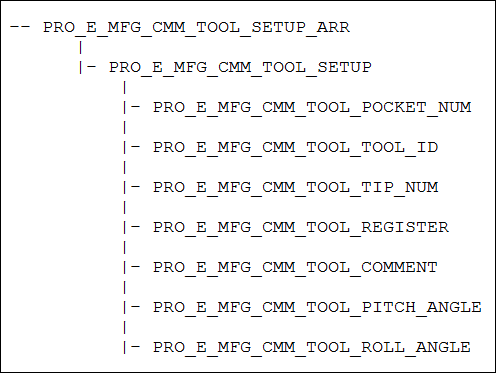

The Roughing Feature Element Tree:

The element tree for the milling roughing sequence is documented in the header file ProMfgFeatRoughing.h, and is as shown in the following figure:

Element Tree for Roughing feature

The following table describes the elements in the element tree for the Roughing feature.

|

Element ID

|

Data Type

|

Description

|

|---|---|---|

|

PRO_E_FEATURE_TYPE

|

PRO_VALUE_TYPE_INT

|

Mandatory element. Specifies the type of the feature. The valid value for this element is PRO_FEAT_MILL.

|

|

PRO_E_STD_FEATURE_NAME

|

PRO_VALUE_TYPE_WSTRING

|

Optional element. Specifies the name for the Creo NC sequence. The default value is Roughing_1.

|

|

PRO_E_NCSEQ_TYPE

|

PRO_VALUE_TYPE_INT

|

Mandatory element. Specifies the type of Creo NC sequence. The valid value for this element is PRO_NCSEQ_ROUGHVOL_MILL.

|

|

PRO_E_MFG_OPER_REF

|

PRO_VALUE_TYPE_SELECTION

|

Mandatory element. Specifies the operation feature selection.

|

|

PRO_E_NCSEQ_CSYS

|

PRO_VALUE_TYPE_SELECTION

|

Mandatory element. Specifies the datum coordinate system that will be used as the coordinate system for the Creo NC sequence.

|

|

PRO_E_RETR_SURF

|

Compound

|

Mandatory compound element. Specifies retract definition. For more information, refer to the section Retract Elements.

|

|

PRO_E_MFG_SUB_SPINDLE_OPT

|

PRO_VALUE_TYPE_INT

|

Optional Element. Specifies the type of spindle assigned to the sequence. This element can be used when two parts are machined

during the same operation in different spindles, that is in the main spindle and in the sub spindle. The valid values for

this element are defined by the enumerated type ProSubSpindleOpt. For more information on the values of ProSubSpindleOpt, refer to the section Spindle Types

|

|

PRO_E_MFG_TOOL_REF_COMPOUND

|

Compound

|

Mandatory compound element. Specifies tool reference definition. For more information, refer to the section Tool Reference.

|

|

PRO_E_MFG_TOOL_ADAPTER_NAME

|

PRO_VALUE_TYPE_WSTRING

|

Optional element. Specifies the tool adapter model name.

|

|

PRO_E_MFG_PARAM_SITE_NAME

|

PRO_VALUE_TYPE_WSTRING

|

Optional element. Specifies the name of the site file with default values for manufacturing parameters.

Note

The site file name will be ignored if the site does not exist in the manufacturing model.

|

|

PRO_E_MFG_PARAM_ARR

|

Array

|

Mandatory element. Defines an array of manufacturing parameters. For more information, refer to the section Manufacturing Parameters.

|

|

PRO_E_MFG_CMP_MILL_WIND

|

Compound

|

Mandatory compound element. Specifies the mill window compound definition. For more information, refer to the section Surface Collection with Mill Window.

|

|

PRO_E_TOOL_MTN_ARR

|

Array

|

Mandatory element. Specifies an array of tool motions.

|

|

PRO_E_TOOL_MTN

|

Compound

|

Mandatory compound element. Specifies the tool motion compound specifications. The applicable tool motion type for this element

is : PRO_TM_TYPE_AUTOMATIC_CUT.

For more information, refer to the section Tool Motion — Auto Cut.

|

|

PRO_E_MFG_START_PNT

|

PRO_VALUE_TYPE_SELECTION

|

Optional element. Specifies the datum point selection. It allows to start the machining at the specified position.

|

|

PRO_E_MFG_END_PNT

|

PRO_VALUE_TYPE_SELECTION

|

Optional element. Specifies the datum point selection. It allows to end the machining at the specified position.

|

|

PRO_E_MFG_PREREQUISITE_ARR

|

Array

|

Optional element. This array specifies the Ids of the prerequisite sequences. For more information, refer to the section Sequence Prerequisites.

|

|

PRO_E_MFG_PROCESS_REF

|

PRO_VALUE_TYPE_SELECTION

|

Optional element. Specifies the reference selections such as part, feature, curve, surface, datum plane, axis, point, and

datum coordinate. It allows you to create additional geometric references to be used only in special process application.

This element supports multiple selections.

|

|

PRO_E_MFG_FEAT_VIEW_NAME

|

PRO_VALUE_TYPE_WSTRING

|

Optional element. Specifies the name of the view. This element allows you to associate a specific view with the machining

step.

Note

This element is used only in special process application.

|

|

PRO_E_MFG_SIMP_REP_NAME

|

PRO_VALUE_TYPE_WSTRING

|

Optional element. Specifies the simplified representation name. This element allows you to associate the specific simplified

representation with the machining step.

Note

This element is used only in special process application.

|

|

PRO_E_MFG_TIME_ESTIMATE

|

PRO_VALUE_TYPE_DOUBLE

|

Optional element. Specifies the time estimated for the machining step.

Note

This element is used only in special process application.

|

|

PRO_E_MFG_COST_ESTIMATE

|

PRO_VALUE_TYPE_DOUBLE

|

Optional element. Specifies the cost estimate for the machining step.

Note

This element is used only in special process application.

|

|

PRO_E_MFG_TIME_ACTUAL

|

PRO_VALUE_TYPE_DOUBLE

|

Optional element. Specifies the actual time for the machining step.

Note

This element is used only in special process application.

|

|

PRO_E_MFG_COMMENTS

|

PRO_VALUE_TYPE_WSTRING

|

Specifies the sequence comments.

|